The Role of Hardness Testers in Material Strength Assessment

The Role of Hardness Testers in Material Strength Assessment

Introduction:

Material strength assessment plays a vital role in various industries, including manufacturing, construction, and aerospace. Determining the hardness of a material is one of the key factors in assessing its strength and durability. Hardness testers are widely used tools to measure the hardness of different materials. This article explores the significance of hardness testers in material strength assessment and their role in ensuring the reliability and quality of various products.

1. Understanding Hardness Testing:

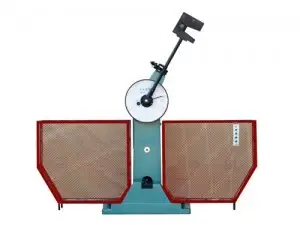

Hardness is the resistance of a material to deformation, denting, scratching, or penetration. It provides valuable information about the material's ability to withstand applied forces. Hardness testing involves various methods, such as indentation, rebound, or scratching, to determine the hardness of a material. Hardness testers are specifically designed instruments used to perform these tests accurately and swiftly.

2. Importance of Material Hardness:

Material hardness is a critical property that impacts the overall performance and lifespan of products. It helps in selecting appropriate materials for specific applications, estimating their durability, predicting wear resistance, and evaluating their ability to withstand adverse conditions. By assessing material hardness, engineers and manufacturers can make informed decisions about material selection, manufacturing processes, and quality control measures.

3. Types of Hardness Testing:

There are several methods available for hardness testing, including Rockwell, Brinell, Vickers, and Knoop hardness tests. Each method employs a different principle and indenter to measure the hardness of various materials. Hardness testers are capable of performing multiple testing methods, enabling users to choose the most suitable method for their specific requirements. This versatility makes hardness testers an essential tool in material strength assessment.

4. Non-Destructive Testing:

One of the key advantages of using hardness testers is that they allow non-destructive testing of materials. Traditional destructive testing often involves cutting or damaging the material to evaluate its strength. However, with hardness testers, a small indenter is used to make an indentation on the material's surface, leaving it virtually unscathed. This makes it possible to test on finished products or critical components without compromising their integrity, ensuring cost-effective and efficient quality control processes.

5. Quality Control and Compliance:

In industries where materials are subjected to stringent quality control standards, hardness testing plays a vital role. Hardness testers help in inspecting raw materials, verifying the quality of incoming materials, and monitoring the consistency of manufacturing processes. By ensuring that materials meet the required hardness specifications, manufacturers can avoid product failures, subsequent recalls, and potential safety hazards. Compliance with industry standards and regulations becomes easier with the aid of hardness testers.

6. Enhancing Product Design:

Hardness testing not only helps in assessing material strength but also aids in product design. By understanding the hardness of different materials, engineers can make informed decisions regarding material selection and the design of efficient and durable products. For instance, in automotive manufacturing, hardness testing of various components such as engine parts, gears, and shafts ensures that they meet the required hardness levels, thereby enhancing reliability and performance.

7. Preventing Catastrophic Failures:

Failure of critical components or materials can have severe consequences, both in terms of safety and cost. Hardness testing plays a crucial role in identifying potential weaknesses or defects in materials before they lead to catastrophic failures. By detecting inconsistencies in hardness, manufacturers can take preventive measures such as heat treatment, surface coating, or appropriate quality control actions to eliminate potential risks.

Conclusion:

Material strength assessment is essential for ensuring the reliability, durability, and safety of various products across industries. Hardness testers provide a valuable means to accurately determine the hardness of materials without compromising their integrity. From quality control to product design, hardness testing plays a crucial role in maintaining high standards and preventing failures. As technology advances, hardness testers continue to evolve, offering more sophisticated features and capabilities, further enhancing their role in material strength assessment.