Unlocking The Power Of Material Testing Machines: The Key To Quality Control And Innovation

- Importance of Material Testing Machines in Quality Control

- Types of Material Testing Machines and Their Applications

Material testing machines play a critical role in ensuring the quality of materials used in various industries, from construction to manufacturing. These machines are essential for testing the mechanical properties of materials and determining their suitability for specific applications. In this article, we will explore the different types of material testing machines available and their applications in quality control and innovation.

One of the most common types of material testing machines is the universal testing machine (UTM). UTMs are versatile machines that can perform various tests, including tension, compression, flexure, and shear tests. These tests help determine the strength, elasticity, and ductility of materials, providing essential data for engineers and researchers.

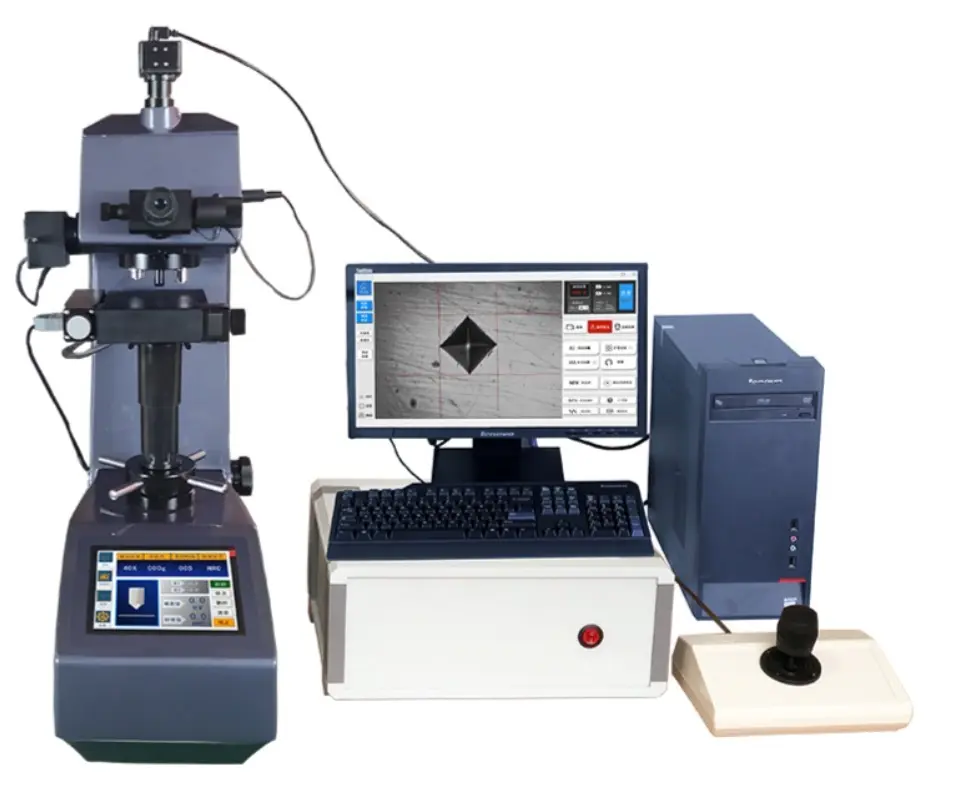

Another type of material testing machine is the hardness tester. Hardness testers measure the resistance of a material to indentation or penetration, providing valuable information about its hardness and wear resistance. This information is crucial for selecting materials for applications where hardness is a critical factor, such as in the automotive and aerospace industries.

Fatigue testing machines are used to evaluate the fatigue strength of materials, which is their ability to withstand repeated loading and unloading cycles. Fatigue testing is essential for ensuring the reliability and durability of materials in applications subject to cyclic loading, such as in structural components and machinery.

Impact testing machines are used to assess the impact resistance of materials, which is their ability to absorb energy when subjected to sudden, high-velocity forces. Impact testing is crucial for evaluating the toughness and fracture toughness of materials used in applications where impact loads are a concern, such as in automotive crash testing and structural engineering.

Creep testing machines are designed to measure the creep behavior of materials, which is their tendency to deform under constant stress over time. Creep testing is essential for evaluating the long-term performance of materials in high-temperature and high-stress environments, such as in power plants and aerospace components.

In summary, material testing machines play a crucial role in quality control and innovation by providing valuable data on the mechanical properties of materials. By understanding the different types of material testing machines and their applications, engineers and researchers can ensure the reliability, durability, and performance of materials in various industries. Whether testing the tensile strength of a steel beam or the impact resistance of a composite material, material testing machines are the key to unlocking the power of materials in modern technology.

- Benefits of Utilizing Material Testing Machines for Innovation

Material testing machines are essential tools in the manufacturing industry for ensuring the quality of materials and products. These machines play a crucial role in quality control and innovation by providing valuable data and insights that help companies improve their processes and products. By utilizing material testing machines, companies can unlock a wide range of benefits that ultimately lead to increased efficiency, cost savings, and overall success.

One of the key benefits of using material testing machines is their ability to accurately measure the properties and performance of different materials. These machines are equipped with advanced technology that allows for precise testing of various characteristics such as strength, durability, elasticity, and thermal conductivity. By obtaining accurate data on these properties, manufacturers can make informed decisions about the materials they use in their products, ensuring they meet quality standards and regulatory requirements.

In addition to measuring material properties, material testing machines also play a crucial role in product development and innovation. By testing new materials and prototypes, manufacturers can identify strengths and weaknesses early in the design process, allowing them to make necessary adjustments before full-scale production. This proactive approach not only helps companies improve the quality of their products but also enables them to stay ahead of the competition by introducing new and innovative materials to the market.

Furthermore, material testing machines can help companies identify potential defects or issues in their products before they reach the consumer. By conducting thorough and comprehensive tests on materials and finished products, manufacturers can detect any weaknesses or flaws that could compromise the integrity or safety of their products. This proactive approach to quality control not only helps companies avoid costly recalls or returns but also helps build trust and credibility with customers who expect high-quality products.

Material testing machines are also valuable tools for optimizing manufacturing processes and reducing production costs. By understanding the properties of different materials and how they behave under various conditions, manufacturers can make informed decisions about how to best utilize these materials in their processes. This can lead to improvements in efficiency, waste reduction, and overall cost savings, ultimately contributing to the profitability and success of the company.

In conclusion, material testing machines are integral to quality control and innovation in the manufacturing industry. By leveraging the capabilities of these machines, companies can ensure the quality and reliability of their products, drive innovation through the development of new materials, and optimize manufacturing processes to reduce costs and improve efficiency. As technology continues to advance, material testing machines will play an increasingly important role in helping companies stay competitive and deliver high-quality products to consumers.

- Key Considerations for Selecting the Right Material Testing Machine

- Future Trends in Material Testing Machines for Quality Control and Innovation

Material testing machines are an essential tool in the field of quality control and innovation, playing a crucial role in ensuring the reliability and performance of materials used in various industries. As technology continues to advance, future trends in material testing machines are shaping the way materials are tested and evaluated, driving innovation and pushing the boundaries of what is possible.

One of the key trends in material testing machines is the integration of advanced technologies such as artificial intelligence and machine learning. These technologies have the potential to revolutionize the way materials are tested, offering more accurate and efficient testing processes. By integrating AI algorithms into material testing machines, organizations can analyze data more effectively, identify patterns and trends, and make informed decisions based on real-time data.

Another important trend in material testing machines is the focus on multi-functionality and versatility. As the demand for more complex materials and products increases, material testing machines are being designed to perform a wider range of tests and measurements. This versatility allows organizations to test a variety of materials and evaluate their properties more effectively, leading to improved quality control and innovation.

Furthermore, the development of miniature and portable material testing machines is another emerging trend in the industry. These compact and lightweight machines provide organizations with the flexibility to conduct tests in a wide range of settings, from the laboratory to the field. This portability allows for more convenient and efficient testing processes, enabling organizations to test materials in real-world conditions and make informed decisions quickly.

In addition to technological advancements, the integration of automation and robotics in material testing machines is also a key trend shaping the future of quality control and innovation. By automating the testing process, organizations can increase efficiency, reduce human error, and improve the accuracy of test results. Robotics can perform repetitive tasks with precision and consistency, allowing organizations to streamline their testing processes and focus on more complex tasks that require human intervention.

Overall, material testing machines are vital tools in ensuring the quality and performance of materials in various industries. As technology continues to advance, future trends in material testing machines are driving innovation and pushing the boundaries of what is possible. By embracing these trends and investing in advanced technologies, organizations can unlock the power of material testing machines and stay ahead of the competition.

Conclusion

In conclusion, material testing machines play a vital role in both quality control and innovation in the industry. With 20 years of experience under our belt, we understand the importance of utilizing these machines to ensure the highest standards are met in our products. By unlocking the power of material testing machines, we are able to push boundaries, drive meaningful advancements, and continuously improve the quality of our offerings. Embracing these tools is not just a necessity, but a pathway to future growth and success in the ever-evolving landscape of the industry. Let's continue to harness the power of material testing machines to drive quality control and innovation forward.