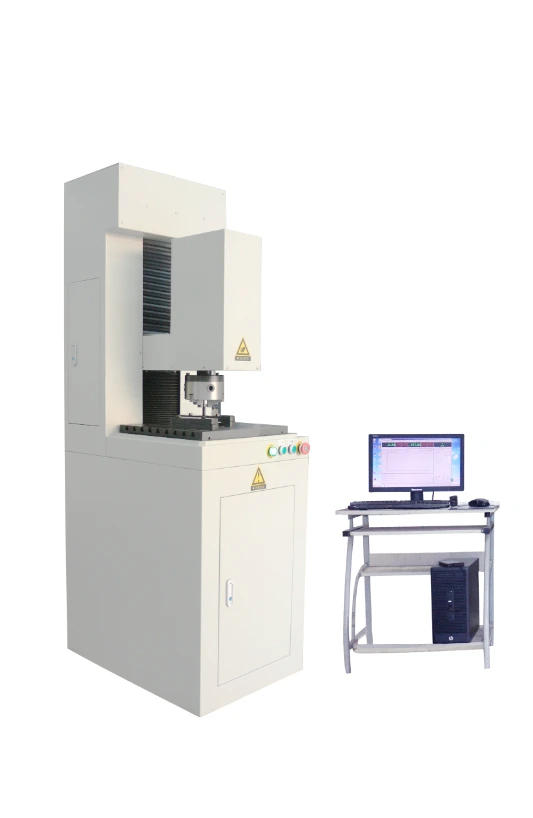

Vertical torsion testing machine

Standards

1. JB/T9370-2015 Technical Conditions for Torsion Testing Machines

2. GB2611-2007 General Technical Requirements for Testing Machines

3. JJG269-2006 Verification Regulations for Torsion Testing Machines

Features

Adopting precision servo motor drive to ensure constant torsional speed;

Precision reducer transmission ensures high efficiency and stability of transmission, with smoother transmission, lower noise, more accurate positioning, and better repeatability of test results;

Adopting high-precision screw rods for higher stability;

Professional high-performance control system, fully automatic measurement;

The electrical control system has high stability, smooth and reliable operation, and fast response;

Simple and easy to operate, the highly simplified control system places all the tedious settings in the background for one click start;

Computer control, supporting Windows and Office software, combined with an optimized comprehensive data processing system, with strong data and graphic processing functions, can instantly print complete test reports and torsion torsion angle test curves. Open structure, user-friendly human-machine interface operation, curve drawing mode, and clearer testing process.

Equipped with comprehensive overload protection, emergency stop and other safety protection functions.

Diversified functions, with various control methods such as torque load and axial load automatic control, automatic maintenance, and self programming control, can achieve one machine with multiple functions and multiple uses.

Specifications

|

1 |

Style: Vertical |

|

2 |

Range: ± 50N. m |

|

3 |

Torque measurement range: 1% -100% FS |

|

4 |

Minimum torque reading value: 0.001Nm |

|

5 |

Relative error of torque indication: ± 0.5% |

|

6 |

Relative error of torque repeatability: 0.5% |

|

7 |

Corner measurement range: unlimited |

|

8 |

Direction of torque increase: in both positive and negative directions |

|

9 |

Minimum reading value for corner: 0.01 ° |

|

10 |

Test speed: 0.1-720 °/min |

|

11 |

Relative error of torsional speed indication: ± 0.5% |

|

12 |

Distance between two clamps: 0-300mm |

|

13 |

Power supply: AC 220V ± 10%, 50Hz; |

Functions

1. Automatic display: Real time display of test force, peak value, and test status during the test process;

2. Automatic correspondence: During the experiment, the angle and torque are automatically corresponded;

3. Automatic operation: Input test parameters to automatically complete the test process;

4. Automatic calculation: After the experiment is completed, the results of torsional strength can be automatically calculated;

5. Automatic storage: Experimental data and curves are automatically stored in the computer;

6. Convenient query: Click the query button to query multiple sets of experimental data that have been done;

7. Printing results: The experimental results can be printed out through a printer;

8. Easy to operate: Chinese menu style operation, intuitive and clear;

9. Protection function: In addition to overload protection function, there are also overcurrent and overvoltage protection functions.

10. Conditional storage: The experimental control data and sample conditions can be made into modules, which facilitates batch testing;

11. Automatic transmission: During the test, the torsional speed can automatically change according to a pre-set program

12. Process implementation: The experimental process, measurement, display, and analysis are all completed by a microcomputer;

13. Batch testing: For samples with the same parameters, they can be set once and completed sequentially;

14. Curve traversal: After the experiment is completed, the curve can be reanalyzed;

15. Curve selection: You can choose to display and print curves such as torque time, torque angle time, and torque torque angle;

16. Test report: Form a report, which can be printed and stored;

Standard Configurations

1. Host machine

2. 1 set of servo motor and servo driver

3. 1 set of high-precision bidirectional torque sensors

4. 1 set of precision ball screws

5. 1 set of precision guide pillars

6. 1 set of lifting motor

7. 1 set of high-precision load sensors

8. 1 set of high-precision deceleration system

9. 1 set of collection and control system

10. HSTEST control software set

11. 1 set of random tools

12. 1 set of clamping device

13. 1 set of three jaw chuck for screwdrivers

14. One Lenovo/HP brand business computer

15. One HP color inkjet printer

16. Files: User manual, certificate of conformity, software manual, packing list