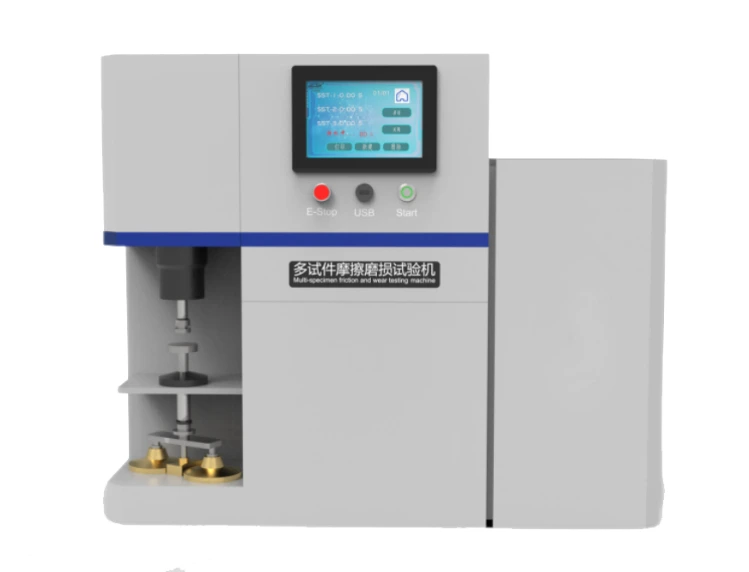

Multi Specimen Friction and Wear Tester

Standards

ASTM D 2266-01 Standard Test Method for Wear Resistance of Lubricating Greases (Four Ball Method)

ASTM D3702-94 Standard test method for determining the wear rate and friction coefficient of materials in self-lubricating frictional contact using a thrust washer testing machine

ASTM D4172-94 Standard Test Method for Wear Resistance of Lubricants (Four Ball Method)

ASTM G 99-04 Standard test method for wear detection using a needle disk tester

Ten speed controls, dual speed range of 60-900100-3600PRM, optional speed ranges of 10-25, 80-1800, 0-450, and 150-7200RPM, with an accuracy of 0.5% of the full range. In addition, the optional low transmission gear controls the speed at 0.1RPM.

Load: Equipped with 2:1 and 10:1 dual range lever control and fixed load, with a weight of 0-801b and a test load of 0-807.51b. The optional pneumatic load can be controlled through a microprocessor control system and data query control system, with a control range of 30-800lbs and an accuracy of 2% or 5-60lbs of full scale. The pneumatic load requires 80psi compressed air and 801b fixed load, and can also be selected as a low load option of 5-60lbs. The load can be automatically displayed in conjunction with the automatic control system and data query system

Temperature control: Random configuration includes thermocouples, digital temperature display, automatic adjustment of set temperature, automatic setting of starting heating, temperature range from room temperature to 150 ℃, optional refrigeration control system, temperature range from room temperature to -30 ℃

Experimental operating environment: lubricated or non lubricated, optional humidity control option, pressure chamber and circulation system motor: 2HP variable speed DC motor, unidirectional or arbitrary vibration, with high and low speeds and low speeds: 20-600 cycles per minute, vibration angle 0-90.The swing angle can be set

Torque

The digital controlled torque measurement unit can be printed directly and automatically cut off.

Abrasion

Continuous pointer display, capable of measuring wear rate and total wear, determined by lever ratio with wear unit intervals of 0.02 or 0.002, optional electronic wear measurement system and data recording and querying system

Test time

Digital timing control, with a counter on the panel that can be set for loop counting

Friction measurement

The torque sensor detects torque by reducing the shaft transmission signal and converts the friction coefficient based on the torque value

Standard (friction method)

Surface: Thrust washer

Line: Vane on Disk

Point: Pin on Disk (Test Pin and Disk)