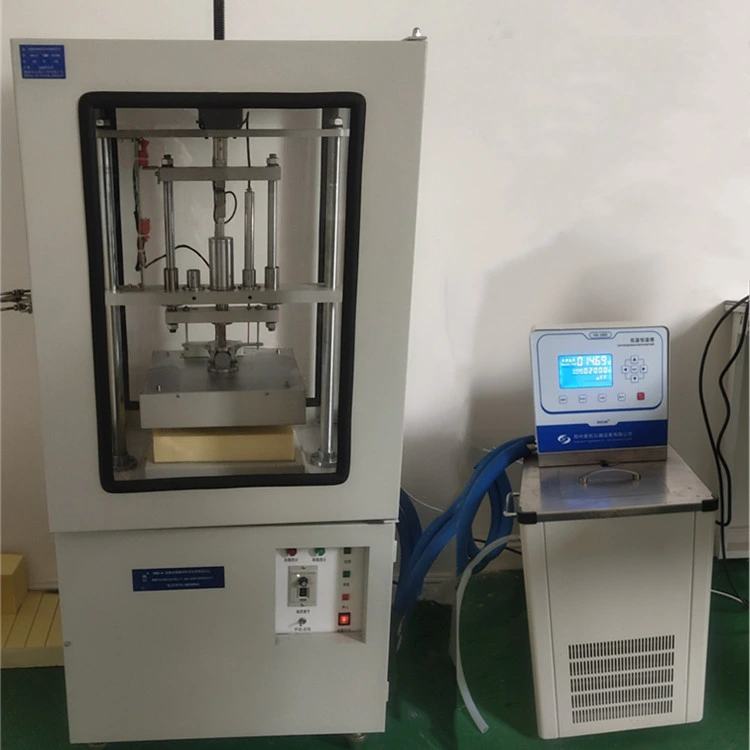

DRPL-III Thermal Conductivity Tester for Insulation Materials (Protective Plate Heat Flow Meter Method)

Standards:GB/T10295-2008 (Determination of steady-state thermal resistance and related characteristics of insulation materials using a heat flux meter method) and ASTM C518-04 (Test method for determining steady-state heat flux and heat transfer characteristics using a heat flux meter method).

System composition

a. Hot surface heater, high-precision programmable temperature control meter, fluctuation less than 0.2 degrees, hot surface temperature measurement resolution 0.01 ℃.

b. The cold surface is controlled by a constant temperature water tank with a fluctuation of less than 0.05 degrees, and the temperature measurement resolution of the cold surface is 0.01 ℃.

C. Heat flow sensor: Optional French imported sensors can be used as needed.

Parameters

1. Thermal conductivity test range: 0.0010-3.0W/MK, displaying four decimal places;

2. Hot surface temperature range: can be tested for two temperature ranges: room temperature -99.99 ℃ and room temperature -350.0 ℃ by changing parameters;

3. Cold noodle temperature range: 0-99.99 ℃, resolution 0.01 ℃;

4. Sample size: 250 × two hundred and fifty × (5-40) mm; Effective test size: 120 * 120mm;

5. Resolution: 0.001wm/k;

6. Test accuracy: better than 3% ± 0.0005 W/MK;

7. Equipped with automatic thickness measurement and reading functions, automatic pressurization and reading functions, electric loading and unloading, adjustable speed, and the pressure of the measured material can be set. The pressurization device is stable and can detect the thermal conductivity and thermal resistance under different pressures;

8. The testing section uses a transparent organic glass windproof cover, with the side door open to show the testing situation inside the instrument.

9. Can detect powder materials;

10. Pressure measurement range: 0-1000N,

11. Displacement measurement range: 0-50.00mm

12. Heat transfer area of hot and cold plates: 250 × 250 (mm), with an additional 300 × 300mm specification is optional.

13. Adjustable spacing between hot and cold plates: 0-50 (mm).

14. Sample testing cycle: about 2 hours.

Instrument completeness

1. 1 main unit of DRPL-III thermal conductivity tester;

2. 1 set of testing software (including communication interface);

3. 1 set of constant temperature water tank and its controller;

4. 1 set of computer printer (configured according to the contract).