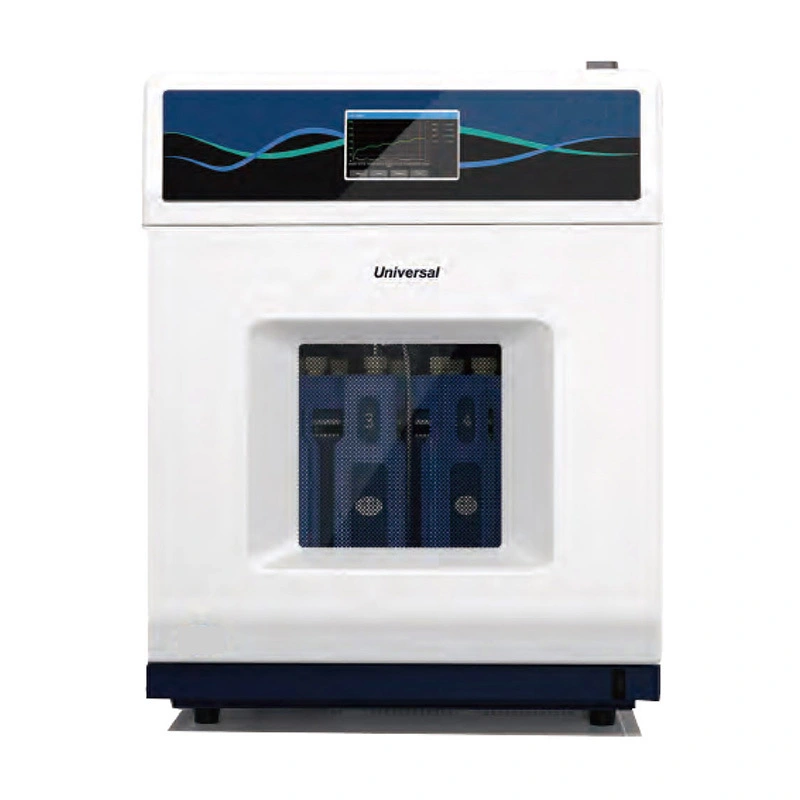

Microwave Digestion Apparatus

The MDA-1 Microwave digestion apparatus is equipped with Android operating system 5-inch color LCD capacitive touch screen, quad-core 1.2GHz processor, 1GB running memory, 8G memory, USB interface. Features functions of real-time display of temperature, time, microwave power, pressure value and curve graph in the reaction system,can set 20 reaction stages step by step, and store the reaction data groups without limitation; also equipped with computer software for playback of experimental data, which can be connected to the host computer in real time through the local area network (WiFi), and the real-time data can be viewed remotely, which makes it easier to analyze the experimental results. And the software will give an alarm for abnormal conditions, and the instrument can be shut down remotely. Equipped with a remote controller which can turn off machine from a long distance in an emergency state under no networking.

Product Specifications

|

Model |

MDA-1-6 |

MDA-1-8 |

MDA-1-10 |

|

Max Output Power |

1000w |

1000w |

1200w |

|

Microwave Source |

2450mhz, Single magnetron frequency system |

2450mhz, Single magnetron frequency system |

2450mhz, Single magnetron frequency system |

|

Grand Power Of Machine |

1900w |

1900w |

1900w |

|

Max Input Power |

1600w |

1600w |

1800w |

|

Batch Process Capacity |

6 |

8 |

10 |

|

Digestion Ttube |

Teflon 100ml |

||

|

Cavity Volume |

45L, 5 layers of Teflon on the surface coating treatment |

||

|

Safety Door |

Specially designed double-protection safety furnace door, multi layer composite integrated type, features high strength, radiation protection, explosion proof, shake wave resistant |

||

|

Pressure Control |

0-6Mpa±0.05Mpa |

||

|

Temp. Control |

0-300℃,±1 ℃ |

||

|

Communication Port |

USB, WIFI |

||

|

Working Environment |

0-40℃, <85%RH |

||

|

Machine Outer Dimensions |

516*737*678mm |

||

Standard Configurations

|

Item |

qty |

|

Main Machine |

1 |

|

PT1000 Thermo Sensor |

1 |

|

6 Station Rotary Disc |

1 |

|

Cup Type Outer Container |

6/8/10 |

|

Digestion Inner Container |

6/8/10 |

|

100ml Digestion Container Holder |

6/8/10 |

|

Top Wire |

6/8/10 |

|

Pressure Measure Tube Assembly |

2 |

|

250V/10A Fuse |

2 |

|

Electric Torque Wrench |

1 |

|

Pressure Sensor Assembly |

1 |

|

Remote Controller |

1 |

|

Peek Pad |

6/8/10 |

|

User Manual |

1 |

Constructions

Temperature and pressure control system

Using high-precision PT1000 contact temperature sensor, detection frequency: 150 to 200 data per second; rate heating: reach the target temperature at a constant speed and accurately within the set time. Temperature sensor range: 0~300℃; temperature measurement accuracy: ±0.1℃; temperature control accuracy ±1℃.

The use of high-precision contact pressure sensor can measure the actual pressure of the reactant, not the estimated value such as waterline pressure measurement, and also avoid the influence of piezoelectric crystal pressure measurement method and the error of the inner tank deformation; pressure sensor range: 0~10MPa; pressure control range: 0~6MPa; pressure measurement accuracy ±0.01Mpa; pressure control accuracy ±0.05Mpa.

Constructions

Multi-Flux Digestion Rotor

The pressure-resistant jacket is made of imported high-strength aerospace composite material PEEK as a whole, which can bear high temperature and high pressure; the upper limit of working temperature is 260℃; the upper limit of working pressure is 6Mpa.

The tank rack adopts a petal-shaped frame structure, which is made of composite materials and has strong pressure bearing capacity; it is equipped with a 6-position digestion rotor to realize easy loading and unloading; the digestion process does not require any consumables.

The inner tank is made of molded modified polytetrafluoroethylene material, which has good compactness, no micropores and good safety performance; good mechanical properties and creep resistance, and the sample can be directly weighed on the balance without the transfer step.

Explosion-proof design: The tank body is designed for vertical directional blasting to avoid lateral impact;

Constructions

Cooling system

Cooling method: Forced rapid air cooling in the furnace cavity, using a corrosion-resistant centrifugal fan with a large air volume, the exhaust air volume is 4M³/min. After the reaction is completed, the microwave stops emitting, the turntable and the fan continue to work, and the temperature in the tank is cooled to After 40 ℃, the instrument automatically buzzes to remind.

Software control system

Equipped with Android operating system 5-inch color LCD capacitive touch screen, quad-core 1.2GHz processor, 1G running memory, 8G memory, USB interface, real-time display of real-time values and graphs of temperature, time, microwave power, and pressure in the reaction system, The instrument can set 20 reaction stages step by step, and can store reaction data sets according to requirements;

The host computer software for playing back the experimental data is randomly equipped, which can be connected to the PC host computer in real time through the local area network (WiFi), and the real-time temperature, pressure, microwave power and other experimental parameters can be viewed remotely, which is convenient for analyzing the experimental results. The abnormal situation will be alarmed, and the instrument can be shut down remotely. Equipped with a remote control device to stop the response from a long distance in an emergency state that is not connected to the Internet.