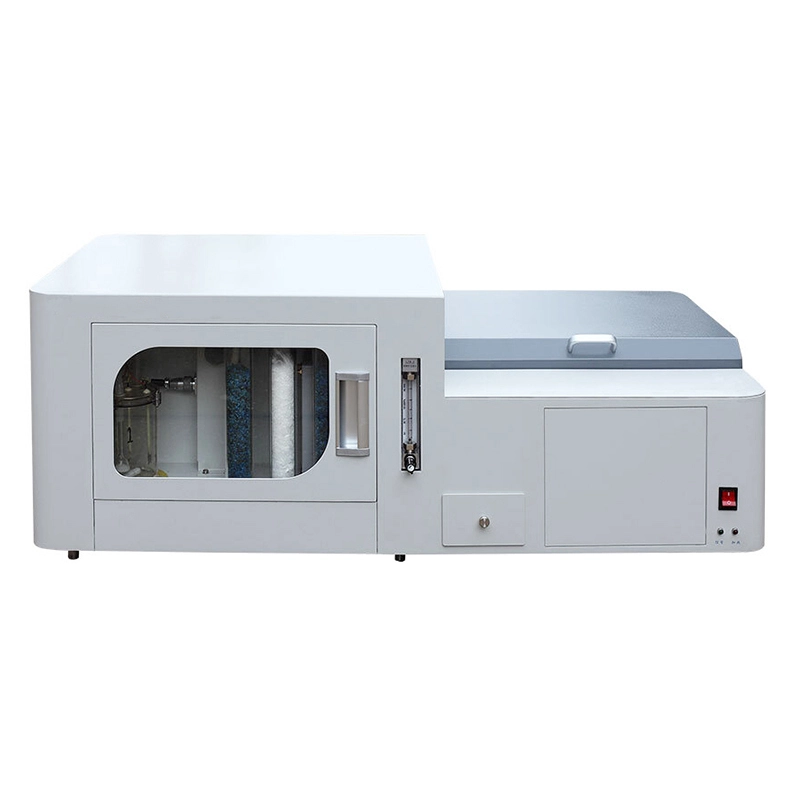

Automatic total sulfur content analyzer Coulometric titration method

Features

◎ The horizontal

integrated structure is adopted to skillfully combine the automatic sample

feeding, sample injection mechanism, high-temperature cracking furnace,

electrolytic cell, agitator, air purification system and other components,

making the instrument more compact, reasonable and stable;

◎ Special flat

bottom corundum porcelain boat is used to reduce the possibility of sample

jamming. Automatic temperature rise, temperature control, sample delivery and

measurement are realized by program control. The results are automatically

saved and printed, and samples can be added in the middle, which greatly

improves the work efficiency and truly realizes unattended;

◎ The coulometric

titration method is adopted for the determination. The determination time can

be automatically judged according to different samples, and the speed is

superior to the Eska gravimetric method and the high-temperature combustion

neutralization method;

◎ Adopt linear

electrolyte molecular concentration collection circuit to effectively solve the

over electrolysis problem;

◎ Contactless switch

is adopted, with measures of couple breaking protection, hardware over

temperature protection and electrolyte backflow prevention;

◎ Multi point

dynamic coefficient correction method is adopted to ensure higher accuracy of

coal test results with high, medium and low sulfur content;

◎ It can be

connected to the laboratory management system to ensure that the balance data

does not fall to the ground, and the test results are backed up and uploaded;

◎ It can be used to

determine the total sulfur content in solid hazardous waste and other samples.

Specifications

|

Model |

MJ-SC-KL24 |

MJ-SC-KL19A |

MJ-SC-KL1 |

|

|

measuring range |

0.01%~40% |

0.01%~40% |

0.01%~40% |

0.01%~40% |

|

Test method |

Coulometric titration |

Coulometric titration |

Coulometric titration |

Coulometric titration |

|

Resolution of sulfur measurement |

0.001% |

0.001% |

0.001% |

0.001% |

|

Working furnace temperature |

1150 ℃(coal, coke), 900 ℃(oil), ±2℃ |

1150 ℃(coal, coke), 900 ℃(oil), ±2℃ |

1150 ℃(coal, coke), 900 ℃(oil), ±2℃ |

1150 ℃(coal, coke), 900 ℃(oil), ±2℃ |

|

Sample mass |

50± 10mg (coal, coke); 100 ± 10mg

(petroleum products) |

50± 10mg (coal, coke); 100 ± 10mg

(petroleum products) |

50± 10mg (coal, coke); 100 ± 10mg

(petroleum products) |

50± 10mg (coal, coke); 100 ± 10mg

(petroleum products) |

|

Sample delivery |

Automatic sample weighing, feeding |

Automatic sample feeding, discarding |

Automatic sample feeding, discarding |

Automatic sample feeding |

|

MCPC module |

√ |

√ |

/ |

/ |

|

Touch screen |

√ |

√ |

/ |

/ |

|

Built-in balance |

√ |

/ |

/ |

/ |

|

Number of samples |

24 |

19 |

19 |

1 |

|

Single sample analysis time |

About 4min |

About 4min |

About 4min |

About 4min |

|

Power |

≤3KW |

≤3KW |

≤3KW |

≤3KW |

|

Working power supply |

AC220V±22V/50H |

AC220V±22V/50H |

AC220V±22V/50H |

AC220V±22V/50H |

|

Overall dimensions |

640×570×820(mm) |

1010×500×380(mm) |

1010×500×380(mm) |

620×500×380(mm) |

|

Net weight |

94kg |

81kg |

78kg |

51kg |