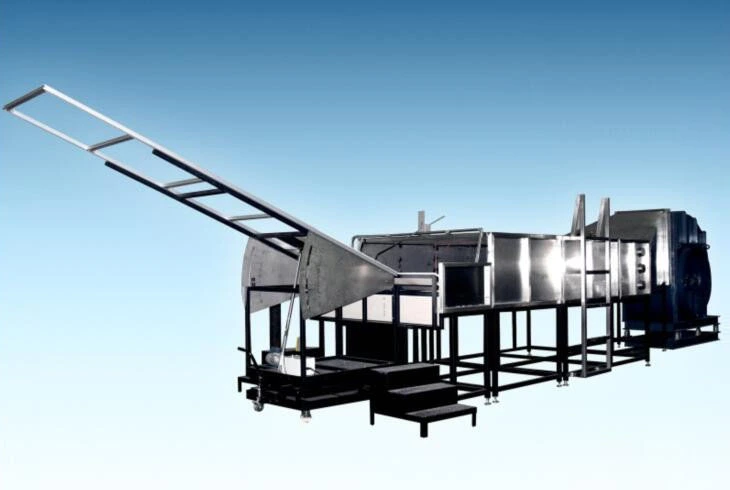

Photovoltaic Module Combustion Testing System

Model

ZR-PM

Features

Features

1. Roof covering material, size: 1300mm (W) × 1000mm (D) × 1200mm (H) for installing test samples;

2. Non combustible test board, installed at the end of the test board, can prevent the occurrence of tempering under the test board;

3. Stainless steel fan-shaped adjustment plate, adjustable testing angle, size: 1440mm (L) x 940mm (H);

4. The main frame is used to support the testing bracket, a corrosion-resistant steel structure, with dimensions of 1020mm (L) x 1000mm (D) x 1473mm (H);

5. Non combustible panel components, installed at the front end of the frame, simulate the eaves and eaves, and extend the flame from the burner to the specimen;

6. The air flow rate on the test bench panel is 19 ± 8 km/h (5.5m/sec) and is monitored by an anemometer;

7. A honeycomb filter is installed in the air duct, and guide vanes are installed at the gas inlet;

8. Adjustable turbulence plates in the air duct can enhance wind speed and reduce turbulence. Made of stainless steel, they will not change position with changes in wind pressure;

9. The air duct material is made of stainless steel, which is corrosion-resistant and high-temperature resistant. The size is 2130mm (W) x 762mm (H) x 3000mm (L);

10. The fan is 220V, 50HZ, three-phase electric, equipped with a reverse system that can automatically adjust the wind speed, with a minimum flow rate of 800m3/min;

11. Gas burner (used for intermittent firing, flame propagation, and flying fire tests), 1.12m long, with a diameter of 60.3mm, and a narrow slit of 12.7mm wide and 0.91m long on the side facing the test plate;

12. The gas burner can provide 22000Btu/min (387kWh) and automatically adjust the gas flow rate according to three combustion levels A, B, and C

13. Automatic ignition system to ensure safety performance during testing. The minimum high pressure of the ignition electrode is 1.8kVp. The mass flow meter controls the gas flow rate according to different standards. Class A&B: 21000~22000 Btu/min (369~387 kWh) for 10 minutes, Class C: 18000~19000 Btu/min (316~334 kWh) for 4 minutes;

14. Brand testing system, providing gas burners with flames that can engulf combustion materials, and gas burner temperature adjustable to 880 ± 10 ℃

15. Metal mesh can support materials to facilitate full combustion of materials;

16. DAQ data acquisition system, the testing software can display testing information such as gas flow rate, gas calorific value, calibration temperature, etc.

Specifications

|

Size |

15200mm (L) x 1900mm (H) x 2200mm (W) |

|

Weight |

970KG |

|

Electrical Requirements |

220 V, 50 Amps; 380V, 15KW |

|

Environmental Temperature |

10 ° C to 35 ° C |

|

Combustion Gas |

methane |